Home

Innovating Healthcare Since 1980

Uma Surgicals Pvt Ltd – Trusted Manufacturer of Orthopaedic, Spine & Maxillofacial Implants, and Surgical Instruments in 30+ Countries.

Exceptional surgical care with compassion, innovation, and integrity.

Who we are

Founded in 1980 in South Mumbai, Uma Surgicals Pvt Ltd has grown into one of India’s most trusted medical device manufacturers. With a legacy of innovation and quality, we specialize in Orthopaedic Implants, Spine & Maxillofacial Implants, Surgical Instruments, and General Surgery Instruments. Our solutions are trusted by hospitals, surgeons, and institutions globally.

Our Vision

To be a global leader in innovative healthcare solutions, continuously integrating advanced technologies, reducing costs, and delivering affordable, high-quality implants and instruments that extend the lifespan of surgical products and improve patient outcomes.

Our Mision

Our mission is to deliver innovative, affordable, and reliable implants and instruments while upholding the highest global quality standards, collaborating with surgeons to design practical solutions, and enhancing health, mobility, and well-being for individuals worldwide.”

- Visual project management

- Team collaboration

- Monitoring Information

Our Values

Innovation

Driving continuous improvements in healthcare technologies.

Integrity

Building trust through ethical business practices and transparency.

Quality

Ensuring precision, safety, and compliance in every product.

Affordability

Making world-class surgical solutions accessible to all.

Collaboration

Working hand-in-hand with surgeons, hospitals, and institutions globally.

Excellence

Setting benchmarks in product design, manufacturing, and service delivery.

Delivering expert surgical care with precision, compassion, and a commitment to patient recovery.

400+ Global Conferences

Successfully participated in over 400 international conferences, showcasing expertise, innovation, and global collaborations.

150+ Live Surgery Workshops

Conducted 150+ live surgery workshops, sharing advanced techniques and hands-on learning with medical professionals worldwide.

Customized Solutions with Surgeons

Delivering innovative, surgeon-driven solutions tailored to patient needs.

ISO & International Standard Quality

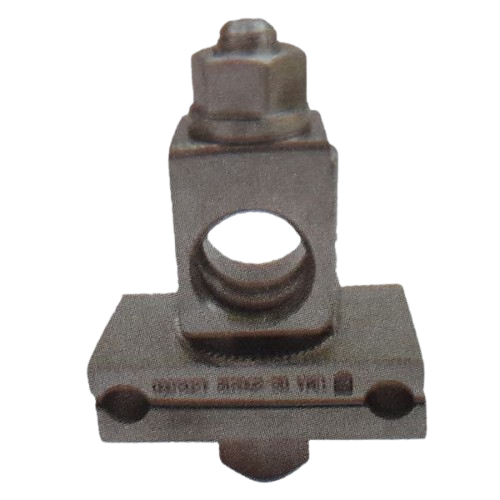

Our Range Of Products

Manufacturing Process – Uma Surgicals Pvt Ltd

01

Raw Material Selection

• High-grade medical stainless steel, titanium, and cobalt-chromium alloys are sourced from certified suppliers.

• Every batch undergoes chemical and mechanical testing to meet ISO, CE, and FDA standards.

02

Precision Forging

& CNC Machining

• CNC (Computer Numerical Control) machines ensure consistent accuracy in dimensions.

• Forging enhances the strength and durability of orthopedic implants.

• Complex geometries for spine and maxillofacial implants are shaped using multi-axis machining centers.

03

Heat Treatment & Hardening

• Implants are heat-treated in controlled furnaces to achieve the required hardness and tensile strength.

• This ensures longer life, higher wear resistance, and load-bearing capacity.

04

Surface Treatment & Polishing

• Surgical implants undergo electropolishing, passivation, and anodizing (for titanium).

• This improves corrosion resistance, biocompatibility, and smooth finish, making implants safe for long-term use inside the body.

• Instruments are mirror-polished for ease of sterilization and longer usability.

05

Quality Control

& Testing

• Each product undergoes dimensional accuracy checks with CMM (Coordinate Measuring Machines).

• Mechanical strength testing ensures implants can withstand real-life surgical stresses.

• Biocompatibility and corrosion tests guarantee patient safety.

• 100% inspection is carried out before packaging.

06

Cleaning & Sterilization

• Ultrasonic cleaning removes microscopic impurities.

• Final sterilization is done in a controlled cleanroom environment.

07

Packaging & Labelling

• Products are packed in sterile, tamper-proof packaging to maintain safety until they reach surgeons.

• Every pack is barcoded/QR coded for traceability and compliance with regulatory requirements.

08

Regulatory Compliance & Certifications

• Manufacturing follows ISO 13485, CE, and WHO-GMP standards.

• Documentation is maintained for traceability, audits, and export compliance.

09

Continuous Improvement

• Regular feedback is collected from surgeons, hospitals, and distributors.

• Our R&D team collaborates with healthcare professionals to co-develop new implants and instruments, ensuring Uma Surgicals Pvt Ltd stays ahead in innovation.

Stay Informed with Health Updates

Evolution of Orthopedic Implants: From Past to Present

Contact Us Evolution of Orthopedic Implants: From Past to Present Orthopedic implants have revolutionized modern medicine, offering patients a second chance at mobility, recovery, and pain-free living. From the early

Importance of Quality Standards in Surgical Implants

Contact Us Importance of Quality Standards in Surgical Implants When it comes to surgical implants, quality is not optional—it is critical. Implants are devices that remain inside the human body

Evolution of Orthopedic Implants: From Past to Present

Contact Us Evolution of Orthopedic Implants: From Past to Present Orthopedic implants have revolutionized modern medicine, offering patients a second chance at mobility, recovery, and pain-free living. From the early…

The Future of Surgical Implants: Innovations Shaping Healthcare

Contact Us The Role of Innovation in Orthopedic Implant Manufacturing The Role of Innovation in Orthopedic Implant Manufacturing The orthopedic implant industry is undergoing rapid transformation, driven by continuous innovation…