- Home

- About Us

Pro

10 day free trial. No credit card required.$75 USD Billed Monthly- Timesheet Scheduler

- People Kiosk

- Shift Scheduling

- -

- -

- -

Team

18 day free trial. No credit card required.$150 USD Billed Monthly- Timesheet Scheduler

- People Kiosk

- Shift Scheduling

- Shift Rotation

- -

- -

Agency

30 day free trial. No credit card required.$400 USD Billed Monthly- Timesheet Scheduler

- People Kiosk

- Shift Scheduling

- Shift Rotation

- Multi-Rater Review

- -

Best ValueEnterprise

+1-750-0616

Consulting Time 8am - 8pm

Custom business solution trailered to your needs

- Recruit (Custom)

- Payroll (Custom)

- Expense (Custom)

- Cliq (Custom)

- Vault (Custom)

- Assessments

- Our Products

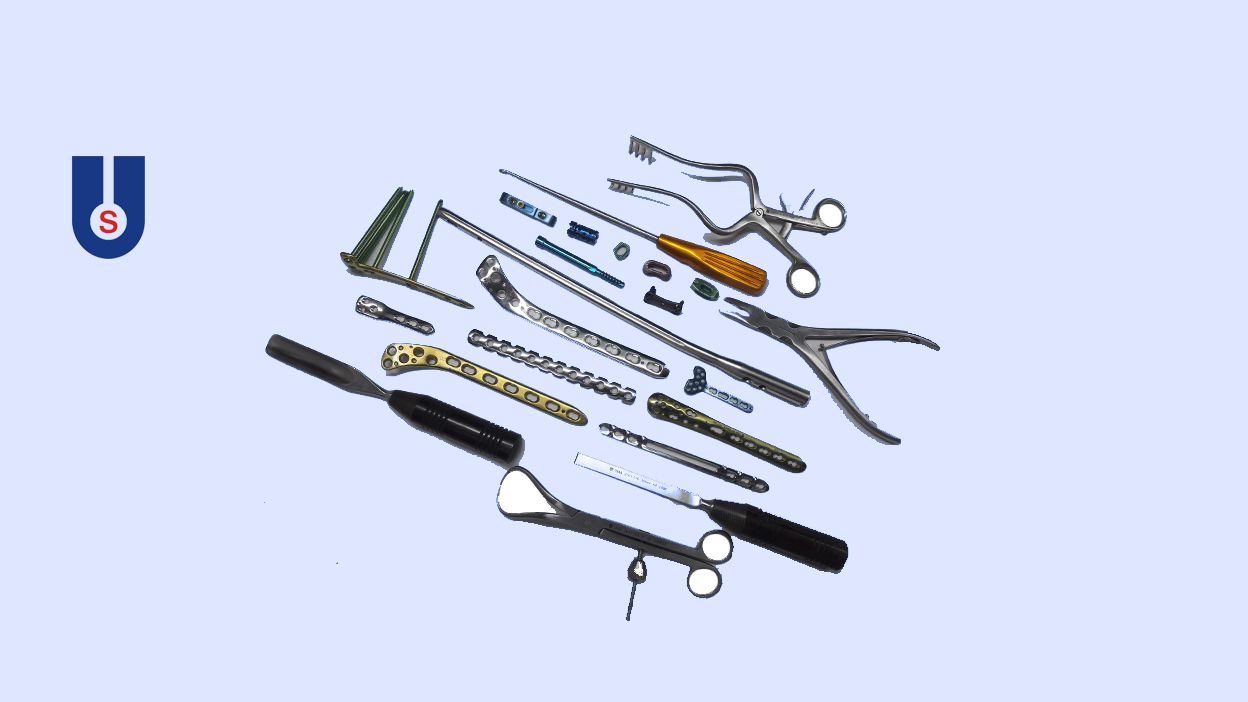

Implant

Pro

10 day free trial. No credit card required.$75 USD Billed Monthly- Timesheet Scheduler

- People Kiosk

- Shift Scheduling

- -

- -

- -

Instrument

Team

18 day free trial. No credit card required.$150 USD Billed Monthly- Timesheet Scheduler

- People Kiosk

- Shift Scheduling

- Shift Rotation

- -

- -

External Fixator

Agency

30 day free trial. No credit card required.$400 USD Billed Monthly- Timesheet Scheduler

- People Kiosk

- Shift Scheduling

- Shift Rotation

- Multi-Rater Review

- -

Best ValueExternal Fixator

Agency

30 day free trial. No credit card required.$400 USD Billed Monthly- Timesheet Scheduler

- People Kiosk

- Shift Scheduling

- Shift Rotation

- Multi-Rater Review

- -

Best Value - We Serve

- Resources

- Contact

About us

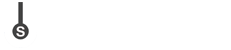

Uma Surgicals Pvt Ltd – Innovating Healthcare Since 1980

We take pride in our active contribution to the medical community, having participated in over 360 global conferences and conducted 120+ live surgery workshops and demonstrations till date.

Founded in 1980 in a small workshop in South Mumbai, Uma Surgicals Pvt Ltd has grown into one of India’s most trusted and pioneering manufacturers of Orthopaedic (Trauma), Spine and Maxillofacial Implants, Surgical Instruments, and General Surgery Instruments.

For over four decades, we have been at the forefront of innovation in the medical device industry, consistently adapting the latest technologies and manufacturing practices to deliver safe, reliable, and cost-effective solutions for healthcare professionals worldwide.

Commitment, Excellence, Integrity: Our Core Beliefs

Our Vision

Our Mission

Our Core Values

• Innovation – Driving continuous improvements in healthcare technologies.

• Integrity – Building trust through ethical business practices and transparency.

• Quality – Ensuring precision, safety, and compliance in every product.

• Affordability – Making world-class surgical solutions accessible to all.

• Collaboration – Working hand-in-hand with surgeons, hospitals, and institutions globally.

• Excellence – Setting benchmarks in product design, manufacturing, and service delivery.

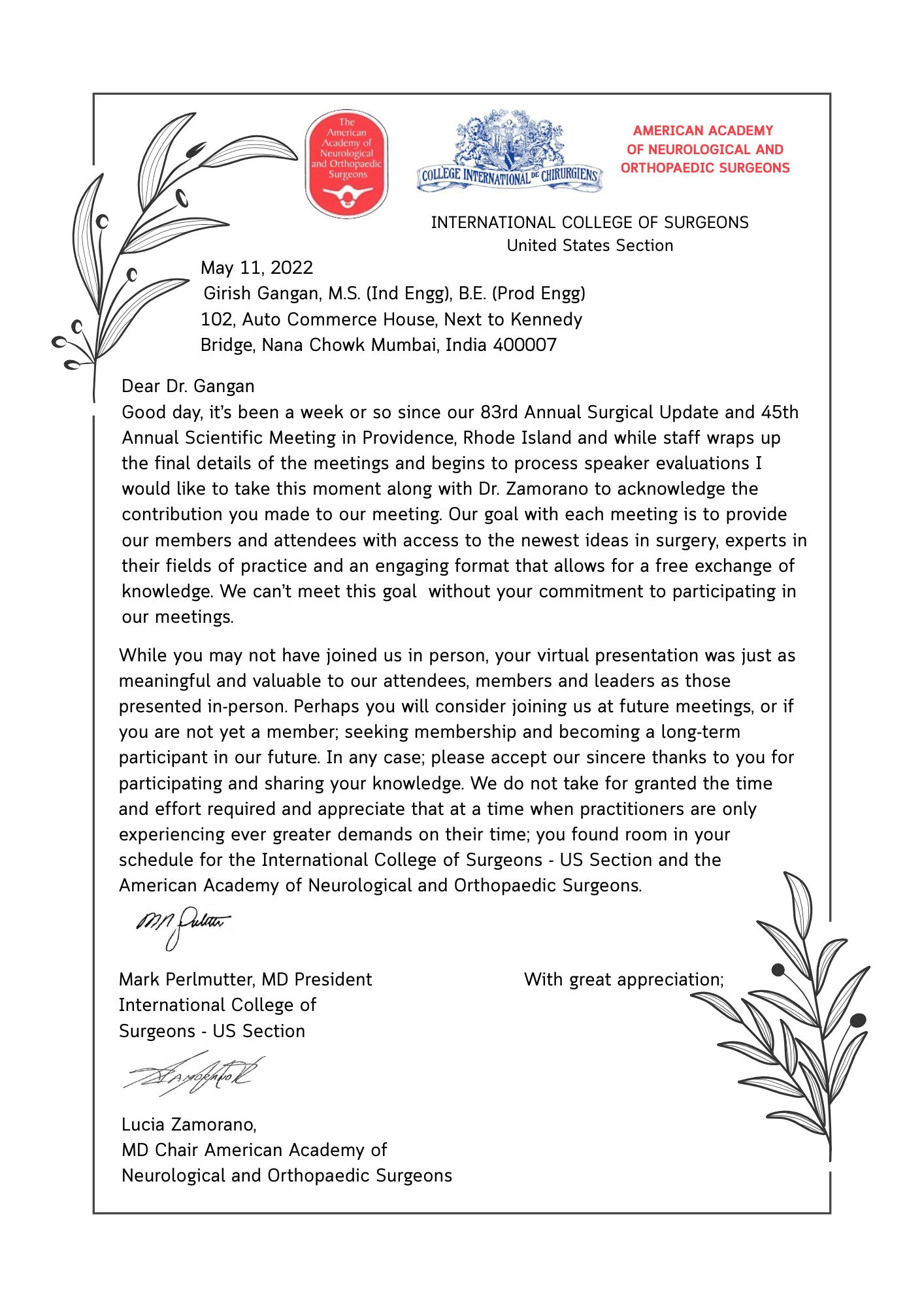

Proudly Recognized by the International College of Surgeons (US Section) and

the American Academy of Neurological & Orthopaedic Surgeons.

Our Core Values

Driving continuous improvements in healthcare technologies.

Building trust through ethical business practices and transparency.

Ensuring precision, safety, and compliance in every product.

Making world-class surgical solutions accessible to all.

Working hand-in-hand with surgeons, hospitals, and institutions globally.

Setting benchmarks in product design, manufacturing, and service delivery.

Company story

We work for better growing result step-by-step

1980

Foundation in South Mumbai

Trade stocks of the biggest names in the international stock market

1990s

Pioneer of Spine Implants manufacturing in India

Trade stocks of the biggest names in the international stock market

2000s

Pioneer of Paediatric Implants manufacturing in India

Trade stocks of the biggest names in the international stock market

2010s

Participation in over 400 conferences and 150+ workshops, with Global presence over 30 Countries

Trade stocks of the biggest names in the international stock market

2020

A new US FDA compliant manufacturing facility with Global presence over 40+ countries

Trade stocks of the biggest names in the international stock market

Why Choose Us

Our team

Meet the Team

MR. Vijay P. Gangan

B.E. (Civil Engg)

Founder and Director

Mr. Girish V. Gangan

M.S. (Indl Engg, USA), B.E. (Prod. Engg, Mumbai)

Managing Director and CEO

Mr. Shirish V. Gangan

B.Sc., Diploma in Business Management

Sales Director

Mrs. Kavita V. Gangan

M.Sc.(Bio Chemistry), B. Sc

UMA

Co-Author of "Third Dimension of Surgery" Book published by CBS Publications.

Testimonials

Clients feedback

Our Manufacturing Process

Raw Material Selection

1. High-grade medical stainless steel, titanium, and cobalt-chromium alloys are sourced from certified suppliers.

2. Every batch undergoes chemical and mechanical testing to meet ISO, CE, and FDA standards.

Precision Forging & CNC Machining

1. CNC (Computer Numerical Control) machines ensure consistent accuracy in dimensions.

2. Forging enhances the strength and durability of orthopedic implants.

3. Complex geometries for spine and maxillofacial implants are shaped using multi-axis machining centers.

Heat Treatment & Hardening

1. Implants are heat-treated in controlled furnaces to achieve the required hardness and tensile strength.

2. This ensures longer life, higher wear resistance, and load-bearing capacity.

Surface Treatment & Polishing

1. Surgical implants undergo electropolishing, passivation, and anodizing (for titanium).

2. This improves corrosion resistance, biocompatibility, and smooth finish, making implants safe for long-term use inside the body.

3. Instruments are mirror-polished for ease of sterilization and longer usability.

Quality Control & Testing

1. Each product undergoes dimensional accuracy checks with CMM (Coordinate Measuring Machines).

2. Mechanical strength testing ensures implants can withstand real-life surgical stresses.

3. Biocompatibility and corrosion tests guarantee patient safety.

4. 100% inspection is carried out before packaging.

Cleaning & Sterilization

1. Ultrasonic cleaning removes microscopic impurities.

2. Final sterilization is done in a controlled cleanroom environment.

Packaging & Labelling

1. Products are packed in sterile, tamper-proof packaging to maintain safety until they reach surgeons.

2. Every pack is barcoded/QR coded for traceability and compliance with regulatory requirements.

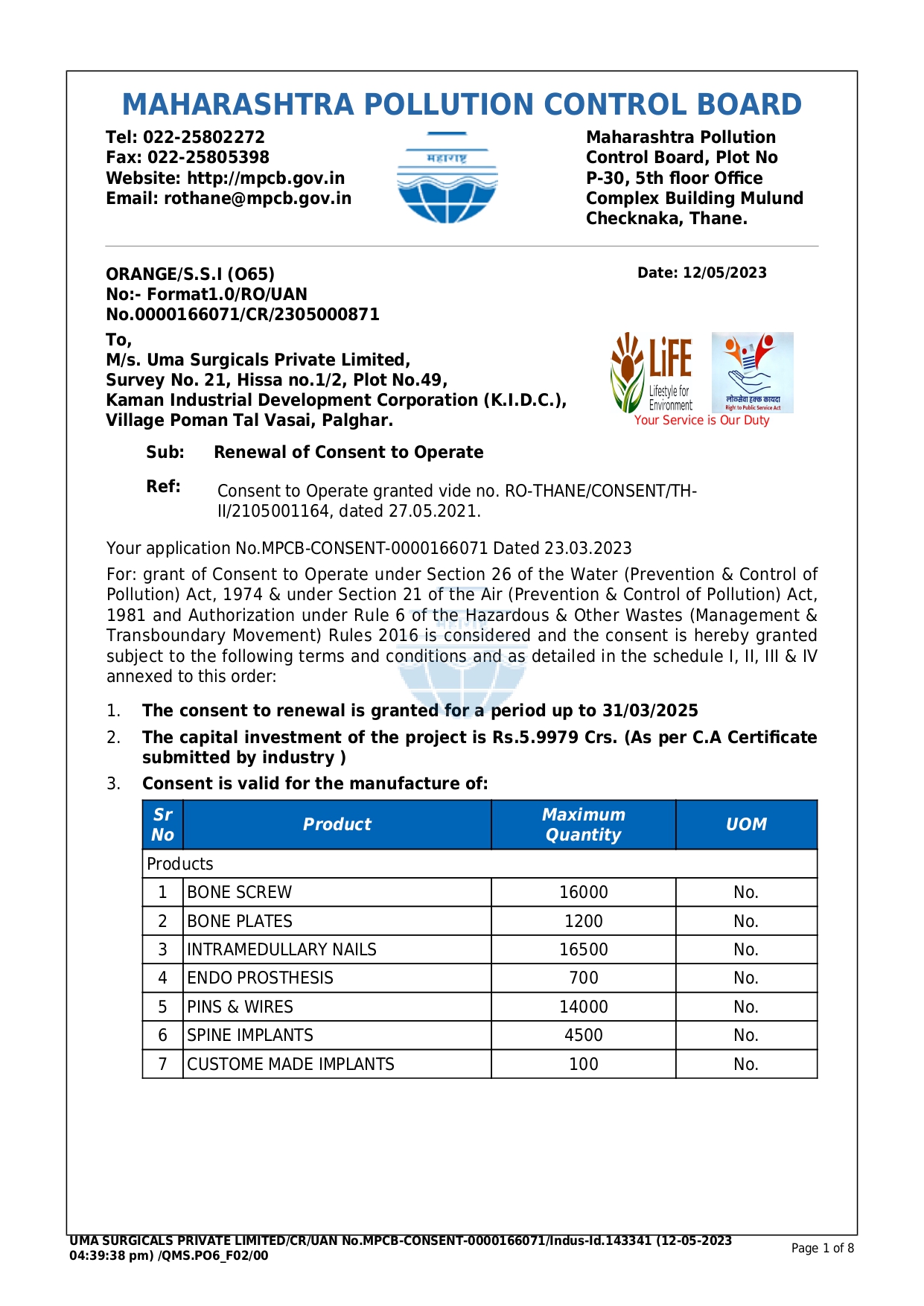

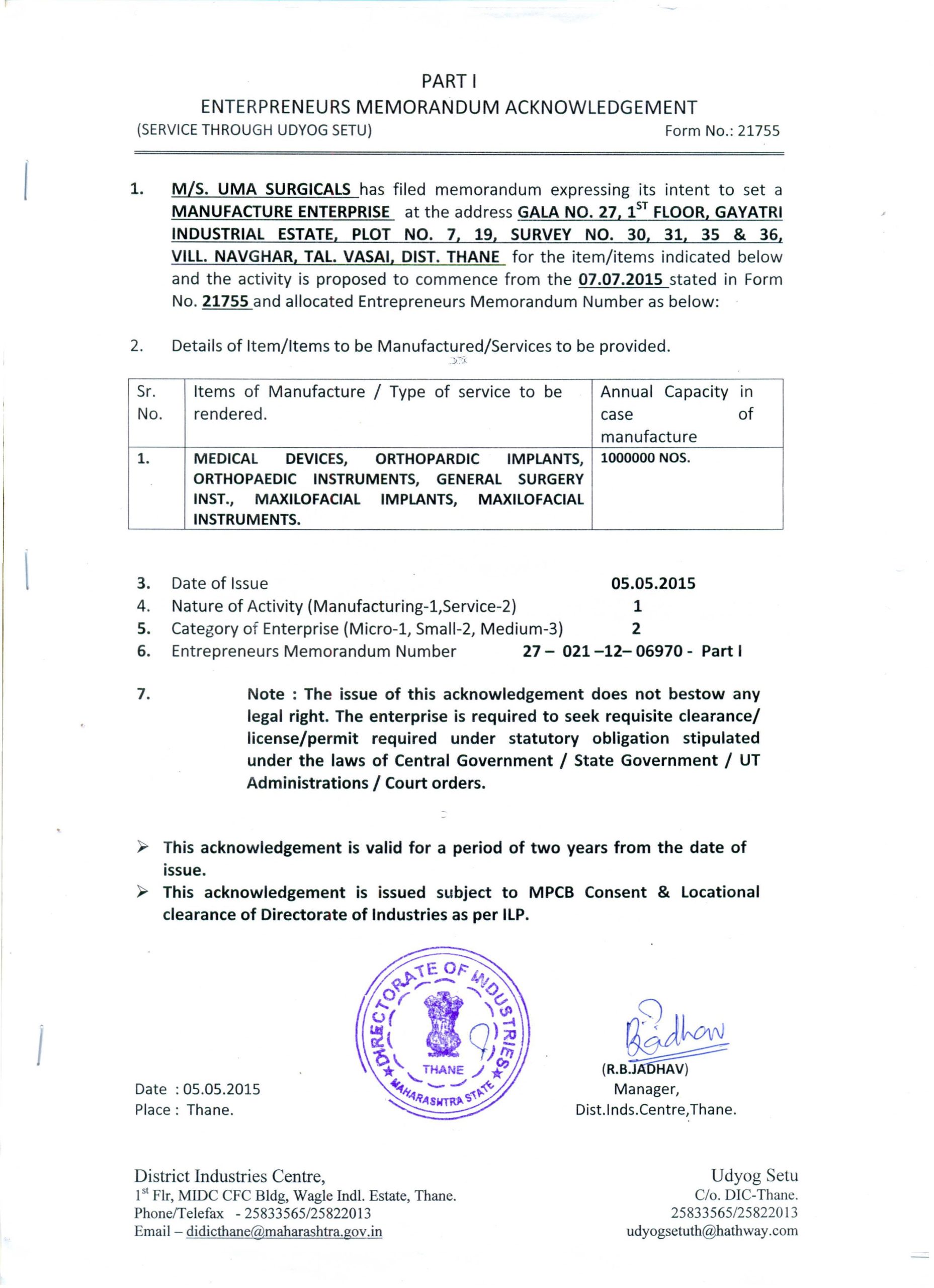

Regulatory Compliance & Certifications

1.Manufacturing follows ISO 13485, CE, and WHO-GMP standards.

2. Documentation is maintained for traceability, audits, and export compliance.

Continuous Improvement

1. Regular feedback is collected from surgeons, hospitals, and distributors.

2. Our R&D team collaborates with healthcare professionals to co-develop new implants and instruments, ensuring Uma Surgicals stays ahead in innovation.

Workshop

Enhancing Skills Through Surgical Workshops

Trust &

Accreditation

Our Certifications

Mumbai

Corporate Office

House, Kennedy Bridge,

Nana Chowk,

Mumbai – 400 007, India.

Company

We build really better idea

Subscribe for newsletter & get day news, service updates

Useful Links

Follow Us

Palghar

Manufacturing Unit

village poman, taluka

vasai , district palghar,

India – 401208